Hardware Testing & Certification

Testing & Certification is a major part of the ODM Plus Solutions portfolio offered by SFO Technologies. We excel in all aspects of test engineering, right from analyzing the design for testability to defining the test requirements, the design of test systems, the creation of test cases and test procedures to cover all performance aspects of the product to the generation of test reports. Circuit testing, Flying probe testing, Optical, and X-Ray inspection, custom built functional test setups, bed of nail testing, boundary scan testing, RF Circuit testing, High Power system testing etc are conducted as per the requirements of the embedded electronics product being developed and manufactured.

Design For Testability

Our test engineers have collectively developed a mammoth set of design rules leveraging our decades of experience in handling complex board level and system level products in domains such as Healthcare, Transportation, Communications, Aerospace & Defence and Energy & Industrial. This expertise enables us to analyze the designs; both made in-house as well as externally; for testability, ensuring the improvement of test coverage, resulting in better yields and reliability of products.

In-Circuit Testing

SFO has been a pioneer in using In-Circuit Testers in India, with the installation of a Schlumberger (later Diagnosys) system in 1994. Currently, we own a number of state of the art systems from Agilent, Teradyne and Aeroflex. Supporting pin counts up to 5000, these systems support boundary scan testing, in-system programming of programmable devices, flash programming, and functional testing. We have the in-house capability to design and develop test fixtures catering to extremely complex and densely packed printed circuit boards.

Our team of well trained and competent test engineers can provide end-to-end service in any aspect of in-circuit testing, including analyzing the design for the availability of accessible test points, designing the bed-of-nails fixture, fabricating and qualifying the fixture, writing test programmes and scripts, and executing the test functions with precision and reliability.

Flying Probe Testing

The Flying Probe Testing provides an easy to use solution to run in-circuit testing without developing a bed of nails fixture, trading in test time against the initial cost of fixture development. Four independently moving probes can make contact with any point on the PCB with accuracy up to 1.25 microns and conduct excitation and measurement. In addition, fixed probes on the bottom side can provide additional test connectivity. This test methodology finds its use in the high mix / low volume business segment of SFO. We have Takaya APT-9411CE test systems that can support boards up to 540mm X 460mm, with test steps up to 320,000.

Automatic Inspection

SFO has equipment that can inspect assembled boards both optically and using X-Rays. The optical inspection focuses on the quality of soldering. The MIRTEC MV-7XI optical inspection system features five cameras, with 10 megapixels capacity, providing resolution up to 9.8 micron per pixel. The machine can handle PCBs of size up to 510mm X 460mm. The system detects solder defects such as lifted pin, cold solder, insufficient solder, solder ball formation, solder bridging etc, enabling the process to qualify the boards to the most exacting and repeatable requirements of IPC standards.

The Automatic X-Ray inspection reveals soldering defects hidden beneath the component packages. This capability becomes very critical to enable the use of dense packages such as ball grid arrays (BGA). The system can also detect inner layer defects in PCBs. The TRI Innovation TR7600 SII system can support PCBs up to 900mm X 460mm. It features six cameras that enable the creation of a 3D image which is analyzed with the intelligent vision system to identify the defects.

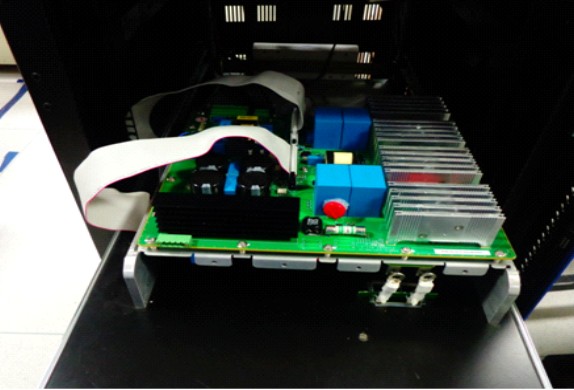

Functional Testing

Our team of test engineers has wide experience in creating test systems for various domains and of varying complexity for hardware and software system development, addressing the three major optimization parametrics viz. test requirement, development time and test cost. The team sports expertise in major test development & automation software tools, such as lab view. A dedicated mechanical team is available for test fixture development including pneumatic, electronic & manual test fixtures with bed of nail connectivity. We take pride in our capability to assimilate deep level knowledge of the system under test and design appropriate test system to ensure that all the product and process requirements are addressed.

Environmental Testing

SFO Technologies possess expertise and facilities for reliability and environmental tests including elevated temperature test up to 85 degree C, thermal cycling @ 15 degree C ramp rate, thermal cycling with 10% to 98% relative humidity and temperature range from +185deg C to -70 deg C. Automated software routines are available for switching on /off the connected load and power to the DUT. Various other reliability and life tests include tests such as cycle life testing of switches and other electromechanical components, solvent resistance tests, Dropping Ball impact testing etc. The expert engineers at SFO are capable of implementing ingenious ways to design and execute long-term life tests of products.

Certifications

There are a number of regulatory requirements to be satisfied before a product could be legally brought into market. These regulations may pertain to various environmental, performance and safety requirements. Each regulatory regime can have its own framework, which makes the process immensely complicated.

SFO Technologies have considerable experience in design, development and certification of a number of products for various regulatory regimes all over the world. The regulatory directives include:

- Electromagnetic Compatibility

- Product Safety

- Electrical and Fire Safety

- Wireless Certification

- Medical Device Safety

All the product development undertaken by SFO go through the process of ‘Design for Compliance’, where the design process addresses all the regulatory requirements right from the planning stage. The design reviews ensure that the design complies with the requirements. ‘Pre-Compliance Testing’ is conducted on prototype units to gain confidence on the actual performance. Any issues found in this stage are corrected before the unit is submitted for testing with nationally accredited test labs for formal testing and certification.

SFO works with all the leading certification agencies, such as the Underwriters Laboratory (UL), TUV, BIS, WPC etc, and have access to worldwide certification regimes via the strategic network of these partnerships.